Price 508000.0 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

Specification

- क्षमता

- पीसी/घंटा

- स्वचालित ग्रेड

- वोल्टेज

- वोल्ट (v)

- पावर

- वाट (w)

- घूमने की गति

- आरपीएम

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- वजन (किग्रा)

- किलोग्राम (kg)

- रंग

- Blue

- वारंटी

- 6 month

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- एफओबी पोर्ट

- Rajkot

- भुगतान की शर्तें

- ,

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- पैकेजिंग का विवरण

- BAG VACUUMING MACHINE

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- प्रमाणपत्रs: CRISIL, ISO: 9001:2015

About

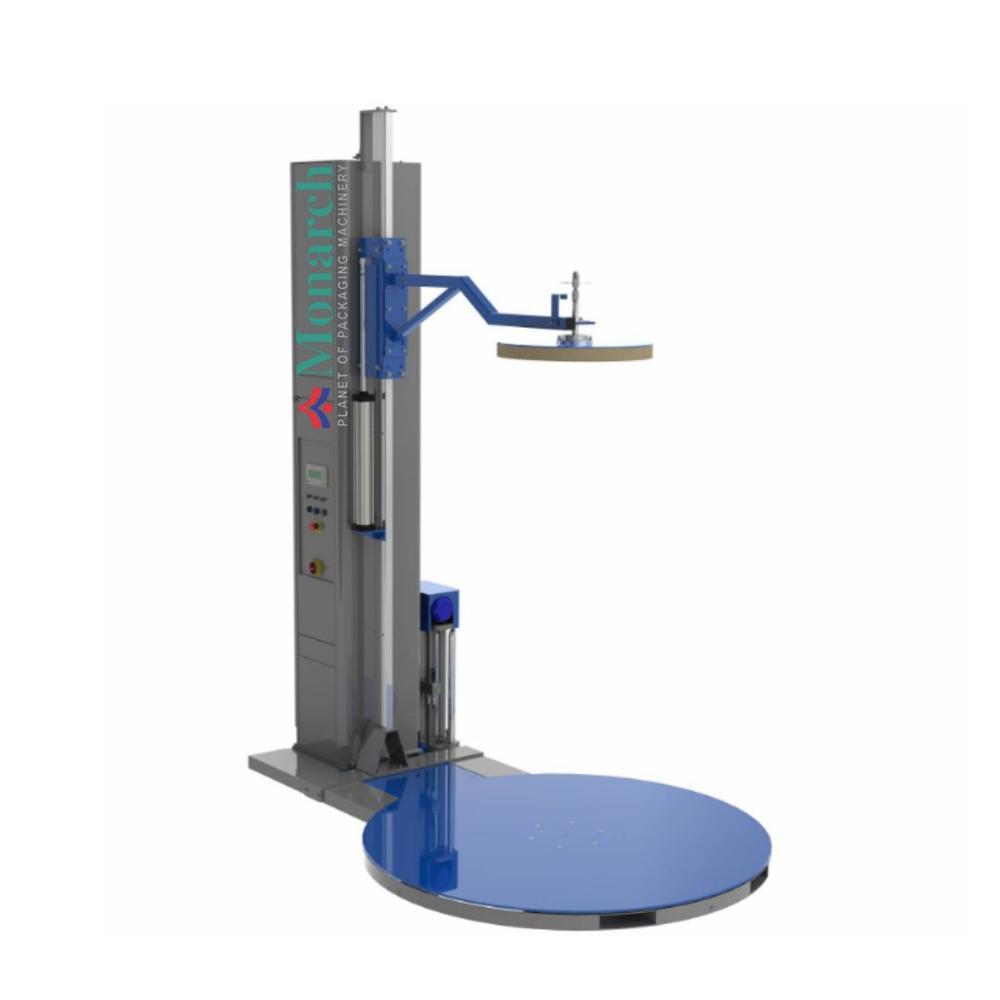

A pallet wrapper machine with a pressing system is designed to wrap products stacked on pallets with stretch film, securing the load for storage or transportation. The pressing system is an additional feature that applies pressure to the pallet load before wrapping, ensuring better stability and minimizing the risk of shifting during handling or shipping.*Product Specification :-

Turn Table Speed = 10rpm

Load Per Hour = 12 to 15 pallet/hr

Working Height = 2400mm

Mx. Loading Weight = 1500kg

Capacity = 12 to 15 PALLETS / HR

Turn Table Speed Adjustable = 0-15rpm

Turn Table Diameter = 1500mm

Machine Dimension (L x w x h) = 2500 x 1500 x 2700 mm

Pressing Motor = 1/2 HP

Top Pressing Attachment = Monitored

Power Requirements = 230/240V , 50Hz , 1

Power Consumption = 2 KW

Efficient Pallet Securing with Pressing System

This pallet wrapping machine ensures your loads are tightly wrapped with its automatic pressing system, which enhances stability during transport. It caters to dynamic warehouse environments and consistently delivers secure packaging, minimizing the risk of product movement.

Robust Design for Heavy-Duty Applications

Manufactured using high-grade materials, the machines blue and silver finish reflects its industrial strength. Its considerable weight and compact footprint combine durability with space efficiency, making it suitable for diverse industries.

User-Friendly Automated Operation

With an automatic grade, this model requires minimal operator intervention. The easy-to-use controls, along with clear indicators, help streamline your pallet wrapping process, reducing manual labor and boosting productivity.

FAQs of Pallet Wrapping Machine with Pressing System:

Q: How does the pressing system enhance pallet wrapping efficiency?

A: The pressing system ensures that the palletized goods remain firmly in place during the wrapping process, minimizing the risk of shifting or instability. This results in tighter, more secure loads, which is particularly beneficial for transporting or storing uneven or delicate items.Q: What is the process for using this automatic pallet wrapping machine?

A: To operate the machine, place the pallet on the turntable, set the required parameters on the control panel, and initiate the automatic cycle. The machine wraps the load at 10 RPM and applies pressure for added stability, with minimal manual input required.Q: When is it ideal to use this pallet wrapping machine?

A: This machine is most suitable in high-volume environments where consistent and secure pallet wrapping is essential, such as warehouses, distribution centers, and manufacturing units. It is designed to wrap up to 5 pallets per hour efficiently.Q: Where can this machine be installed in my facility?

A: The machines compact dimensions (900 x 1300 x 1200 mm) allow for flexible installation in most warehouse or production line settings. Ensure a stable, level floor and access to a 230 or 240 Volt electric supply for optimal operation.Q: What are the benefits of using this pallet wrapping machine with pressing system?

A: The main advantages include improved load stability, reduced labor costs, and increased wrapping consistency. Its robust design and automation ensure efficient operation and help decrease product damage during transportation or storage.Q: What maintenance is required for this wrapping machine?

A: Regularly check for wear and tear, especially on moving parts and the pressing system. Keep the machine clean and follow the manufacturers recommended service intervals to maintain reliable performance and extend the lifespan of the equipment.Q: Who are the main users and suppliers of this equipment?

A: This pallet wrapping machine is typically used by exporters, manufacturers, and suppliers in India who require efficient and secure packaging for various goods. It is supplied by certified vendors supporting industrial packaging needs.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Pallet Stretch Wrapping Machine Category

पैलेट रैपर मशीन

मूल्य या मूल्य सीमा : आईएनआर

स्वचालित ग्रेड : SemiAutomatic

मूल्य की इकाई : टुकड़ा/टुकड़ाs

माप की इकाई : टुकड़ा/टुकड़े

क्षमता : पीसीएस/मिन

वारंटी : 6 MONTH

पैलेट स्ट्रेच रैपिंग मशीन

मूल्य या मूल्य सीमा : आईएनआर

स्वचालित ग्रेड : SemiAutomatic

मूल्य की इकाई : टुकड़ा/टुकड़ाs

माप की इकाई : टुकड़ा/टुकड़े

क्षमता : पीसीएस/मिन

वारंटी : 6 Month

|

MONARCH APPLIANCES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें