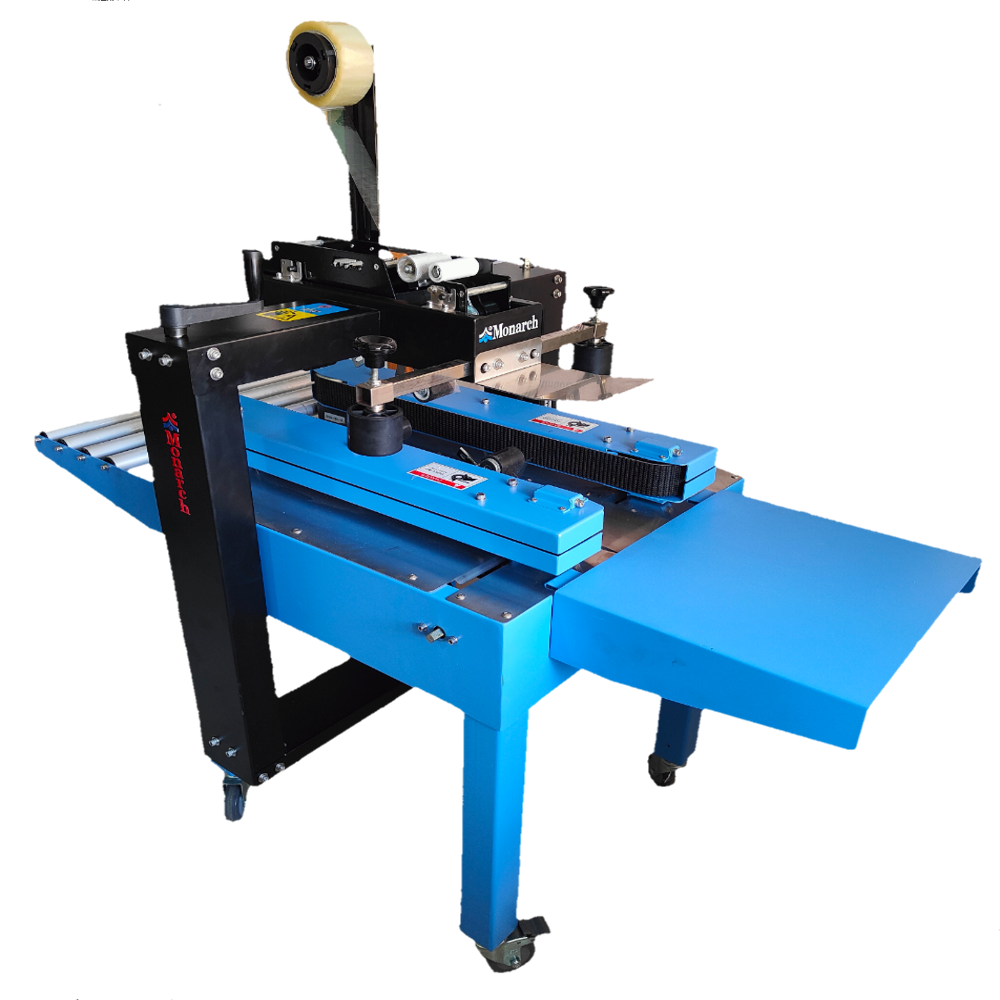

Case Sealer

Price 92000.0 INR/ Piece

Case Sealer Specification

- Power Supply

- 220V AC

- Type

- Packaging Line

- Material

- Mild Steel

- Feature

- Heavy Duty Machine

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Power

- 220 Volt (v)

- Voltage

- 220 Volt (v)

- Weight (kg)

- 88 Kilograms (kg)

- Dimension (L*W*H)

- Millimeter (mm)

- Color

- Blue

- Warranty

- 1 Year

- Sealing Type

- Other

Case Sealer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Case Sealer

This machine have 2 motors for ensuring smooth operation for extra light and heavy cartons.Tape Overlap length can be adjusted.Top & Bottom Drive Type Carton sealing machine.Heavy-Duty Performance for Demanding Environments

Built with premium mild steel, this case sealer offers dependable performance even in fast-paced packaging operations. Its semi-automatic functionality caters to businesses requiring sturdy, efficient, and easy-to-operate sealing solutions. The 88 kg weight ensures stability while processing multiple cases, making it an ideal addition to large scale manufacturing or distribution centers.

Efficient Human Machine Interface Control

The sealer incorporates a Human Machine Interface (HMI) for intuitive control and monitoring, streamlining setup and operations. This user-friendly interface reduces operator training time and enables precise adjustments to improve workflow continuity and packaging accuracy, ensuring that every case is sealed securely to industry standards.

Reliable Support and Flexible Application

Manufactured and exported from India, this case sealer is supplied to a broad range of packaging solutions providers. Its 1-year warranty demonstrates product reliability and the manufacturers commitment to service. Businesses can implement this machine across various applications, from manufacturing lines to warehouse pack-off stations.

FAQs of Case Sealer:

Q: How do I operate the semi-automatic case sealer?

A: Operating the case sealer involves loading your box onto the conveyor, adjusting the settings via the Human Machine Interface, and allowing the electric drive to automatically seal the case flaps. The process is smooth and requires minimal manual handling.Q: What materials and case sizes are compatible with this case sealer?

A: This machine, built from mild steel, accommodates most standard cardboard boxes. Operating dimensions in millimeters allow for flexibility in case sizes, making it suitable for various packaging requirements in different industries.Q: When is it appropriate to use a heavy-duty case sealer?

A: Heavy-duty case sealers are recommended for environments with high packaging volume, such as manufacturing plants or distribution warehouses. They provide enhanced durability and consistent sealing for frequent, large-scale operations.Q: Where can the case sealer be installed within my facility?

A: The case sealers compact footprint allows it to be placed on packaging lines, near warehouse dispatch zones, or integrated into existing packing stations. Ensure the location has a stable surface and access to a 220V AC power supply.Q: What is the process of sealing a case with this machine?

A: After setting up the machine, simply feed the box along the line. The semi-automatic system activates, securely sealing the box flaps as it passes through, thanks to the electric drive and precise controlsreducing labor requirements and increasing efficiency.Q: How does using this case sealer benefit my business?

A: Implementing this sealer improves packaging speed, consistency, and quality, lowering labor costs and reducing the risk of improperly sealed cases. Its rugged mild steel construction and 1-year warranty ensure industry reliability and long-term return on investment.Q: What kind of warranty and support are provided with the case sealer?

A: The machine comes with a 1-year manufacturers warranty, ensuring support for repairs or replacement due to manufacturing defects. As an exporter, manufacturer, and supplier in India, after-sales support is easily accessible for customers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tapping Machine Category

Semi Auto Carton Taping Machine

Price 104000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Type : Other

Voltage : 230 Volt (v)

Automatic Grade : SemiAutomatic

Carton Tapping Machine

Price 95000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Type : Packaging Line

Voltage : 220 Volt (v)

Automatic Grade : SemiAutomatic

Auto Flap Closer Machine

Price 340000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Type : Packaging Line

Voltage : 220 Volt (v)

Automatic Grade : SemiAutomatic

Carton Erector Machine

Price 825000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Type : Packaging Line

Voltage : 220 Volt (v)

Automatic Grade : SemiAutomatic

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry