Fully Automatic Strapping Machine

Price 5500.0 INR/ Piece

Fully Automatic Strapping Machine Specification

- Material

- strapping roll

- Capacity

- 15 Pcs/min

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Selection Mode

- Automatic

- Dimension (L*W*H)

- Millimeter (mm)

- Color

- Gray

- Weight (kg)

- 142 Kilograms (kg)

Fully Automatic Strapping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 3 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Carton packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Fully Automatic Strapping Machine

A fully automatic strapping machine is designed to strap products, bundles, or pallets with a plastic strap (typically made from polypropylene, polyester, or nylon) to ensure they are securely bound for storage, handling, and shipping.These machines are essential in high-volume production environments where efficiency and consistency are crucial.

*PRODUCT SPECIFICATION :-

Product Name -

FULLY AUTO STRAPPING MACHINE

Machine Weight -

142 kg

Power Supply -

Single Phase

Arch Size ( W x H ) -

900 x 600 mm

Strap Width -

9 , 12 mm

Machine Size in mm ( L x W x H ) -

1415 x 615 x 1460

Tension Strength -

90 kg. / Max.

Intuitive Human Machine Interface

Operating this strapping machine is straightforward, thanks to the Human Machine Interface (HMI) control system. The controls are designed for quick learning and ease of use, eliminating the complexities of computerized systems. This allows operators of varying experience levels to manage the packaging process efficiently, enhancing productivity while reducing errors during operation.

Optimized for High Volume Packaging

With a capacity of 15 packages per minute, this fully automatic strapping machine streamlines medium to large-scale packaging requirements. Its robust design and efficient strapping roll material ensure consistent performance, making it perfect for industrial applications where speed and reliability are paramount. The sturdy build can withstand rigorous daily use in demanding environments.

FAQs of Fully Automatic Strapping Machine:

Q: How does the Fully Automatic Strapping Machine operate without computerization?

A: The machine utilizes a Human Machine Interface (HMI) for control, removing the need for complex computerized systems. Operators interact with the intuitive panel to manage strapping settings, allowing for seamless and dependable operation.Q: What materials are compatible with this strapping machine?

A: This strapping machine is designed to work with standard strapping roll materials, commonly used for securing a wide variety of packages across different industries.Q: When is the best time to use a fully automatic strapping machine in packaging processes?

A: The machine is most beneficial during medium to high-volume packaging, such as in warehouses, distribution centers, and manufacturing plants, where speed and consistency are critical.Q: Where can this strapping machine be installed or used effectively?

A: Due to its durability and automatic operation, it is best suited for industrial settings, including logistics hubs, factories, and commercial warehouses, both in India and for export markets.Q: What is the strapping process managed by this machine?

A: Once the package is placed in position, the machine automatically wraps, tightens, and seals the strap securely, completing the cycle rapidly at a rate of up to 15 pieces per minute.Q: How does the machine benefit businesses compared to manual strapping methods?

A: By automating the strapping process, it increases efficiency, reduces manual labor, ensures consistent strap application, and boosts overall packaging productivity.Q: What regular maintenance is required for optimal performance?

A: Routine checks of the strapping roll supply, cleaning of moving parts, and inspection of the HMI are recommended to maintain smooth and uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi Auto / Fully Auto Strapping Machines Category

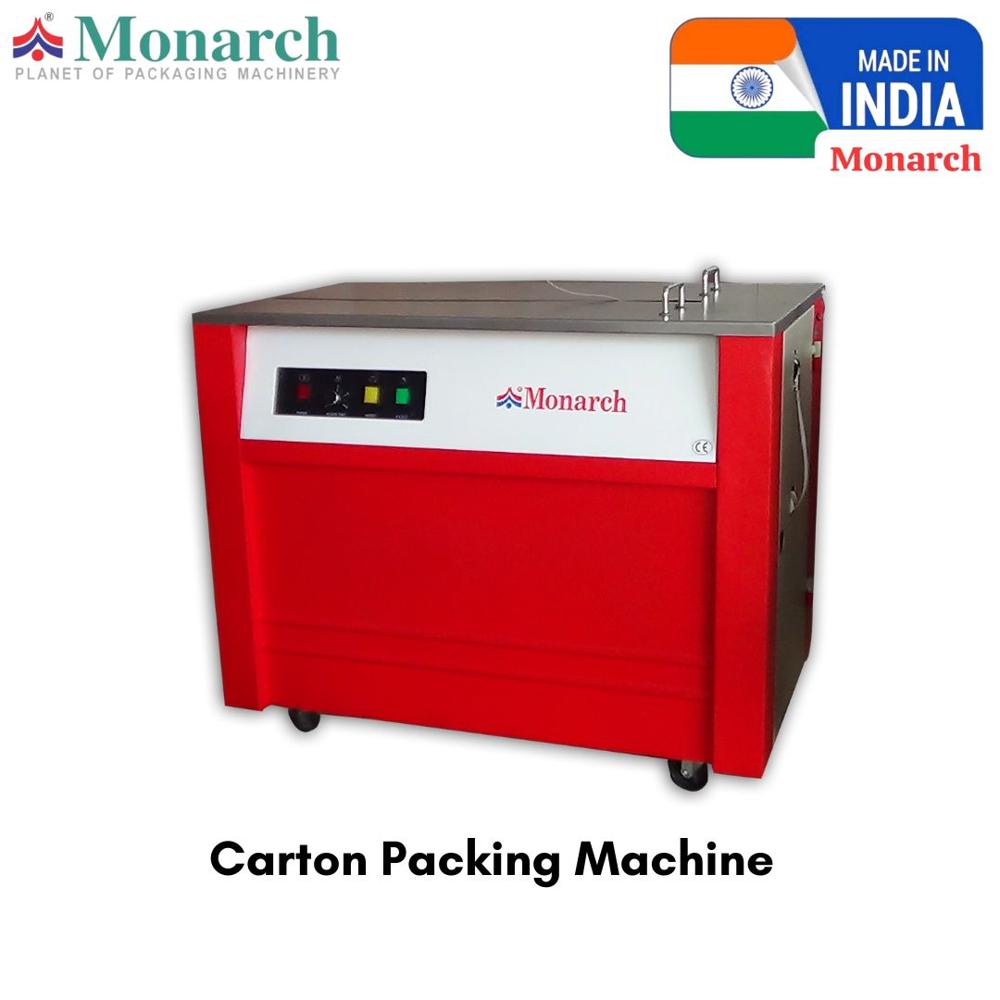

Carton Box Strapping Machine

Price 65000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Strapping roll

Weight (kg) : 100 Kilograms (kg)

Computerized : No

Strapping Machine

Price 32000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Material : Strapping roll

Weight (kg) : 110 Kilograms (kg)

Computerized : No

Fully Auto Strapping Machine

Price 188500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : strapping roll

Weight (kg) : 142 Kilograms (kg)

Computerized : No

Semi auto strapping machine

Price 40300.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : strapping roll

Weight (kg) : 100 Kilograms (kg)

Computerized : No

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry