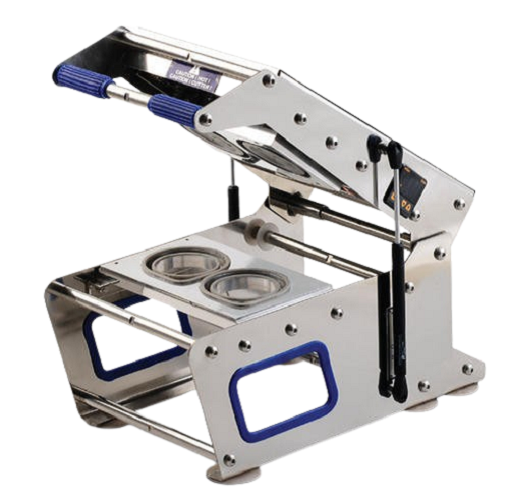

Glass & Cup Sealing Machine

Price 16500.0 INR/ Piece

Glass & Cup Sealing Machine Specification

- Power

- 240 Volt (v)

- Dimension (L*W*H)

- 16 X 8 X 11 Inch (in)

- Automation Grade

- Manual

- Voltage

- 240 Volt (v)

- Sealing Speed

- 6 cup or glass/min

- Weight

- 14 Kilograms (kg)

- Application

- meal tray packing machine for lunch or dinner food

- Driven Type

- Hand Opereted

- Type

- glass packing (MTS 95 R)

- Color

- Silver

- Sealing Type

- plastic film

- Seals Type

- Foil sealing

- Packaging Material

- sealing film

- Packaging Speed

- 6 glass Pieces/Minute

- Condition

- New

Glass & Cup Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Glass & Cup Sealing Machine

Tray Packing Machine:

A tray packing machine is a specialized piece of equipment used for packaging products into trays. It automates the process of arranging, filling,and sealing products into per-formed trays, which are commonly used in various industries, including food and beverage, pharmaceuticals, electronics, and consumer goods. The machine improves efficiency, consistency, and hygiene in the packaging process.

|

PRODUCT SPECIFICATION |

|

|

Product Name |

cup/glass packing machine (MTS 95 R) |

|

Machine Weight |

14 kg |

|

Power Consumption |

300 Watt (240 Volt) |

|

Cup Dia (mm) |

95 mm |

|

Available Container Size (ml) |

110/230/300/350/450 ml |

|

Machine Dimensions in MM (L X W X H) |

420 X 220 X 280 |

Effortless Manual Sealing with Precision

The MTS 95 R Glass & Cup Sealing Machine offers reliable hand-operated sealing for a variety of glass and cup sizes. Its intuitive manual operation empowers users to seal meal trays and food containers consistently, ensuring freshness and spill protection. With a robust stainless steel body and compact design, it suits restaurants, commercial kitchens, and catering businesses looking for compact yet effective packaging solutions.

Versatile Applications for Foodservice

Specially designed for meal tray and food packaging, the machine can efficiently seal multiple types of containers, including cups and glasses for lunch or dinner deliveries. It uses sealing film or foil to offer secure, hygienic, and tamper-evident packaging. This flexibility benefits food exporters, manufacturers, and suppliers seeking to maintain high standards in food presentation and protection.

Enhanced Productivity with Manual Control

Maximizing output without compromising quality, the MTS 95 R delivers a sealing speed of up to 6 cups per minute. The manual drive offers exceptional control over the sealing process, allowing users to achieve consistent results even during busy operations. Its durable construction and straightforward maintenance requirements make it a reliable asset for food businesses in India.

FAQs of Glass & Cup Sealing Machine:

Q: How does the MTS 95 R Glass & Cup Sealing Machine operate?

A: The MTS 95 R is hand-operated, using a manual lever to press and seal a plastic or foil film over glasses, cups, or meal trays. Simply insert the filled container, place the sealing film on top, and pull the lever to create an airtight seal.Q: What types of containers can be sealed with this machine?

A: This machine is designed for glass, cup, and meal tray sealing. It accommodates a variety of sizes suitable for lunch or dinner food packaging, making it an excellent choice for restaurants, caterers, and food suppliers.Q: When should I use this machine for meal tray or cup packing?

A: The machine is ideal for packaging meals during food preparation for delivery, takeout, or catering events. It helps ensure food remains fresh and protected until it reaches the customer.Q: Where can the Glass & Cup Sealing Machine be installed or used?

A: Thanks to its compact size and moderate weight, the MTS 95 R can be stationed on any stable worktable in commercial kitchens, catering facilities, food factories, or small-scale packaging units.Q: What is the process of sealing using the MTS 95 R?

A: Begin by placing the filled cup, glass, or meal tray into the machine. Align the sealing film or foil over the top, then use the hand lever to press and activate the seal. Remove the securely sealed container and repeat the process for subsequent items.Q: What benefits does manual operation provide?

A: Manual operation allows for greater control over each sealing process, reducing the risk of errors and providing consistent, reliable results. It also makes the machine easy to use without requiring specialized technical skills or electrical automation systems.Q: How can using this machine improve food packaging for businesses?

A: By securely sealing meals and beverages, the machine helps extend product freshness, prevents leaks during transport, and enhances the professional appearance of food packages. This supports customer satisfaction and maintains hygiene standards for food exporters, manufacturers, and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tray Glass Sealer Category

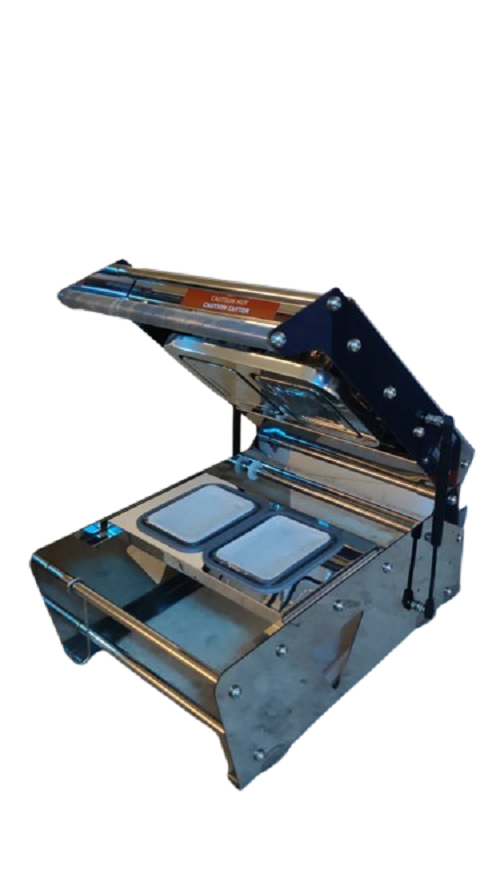

Tray/Thali Sealer Machine Combo (5 / 8 Cp )

Price 31000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 700 Watt (w)

Dimension (L*W*H) : 19 x 15 x 11 Inch (in)

Automation Grade : Manual

Weight : 33 Kilograms (kg)

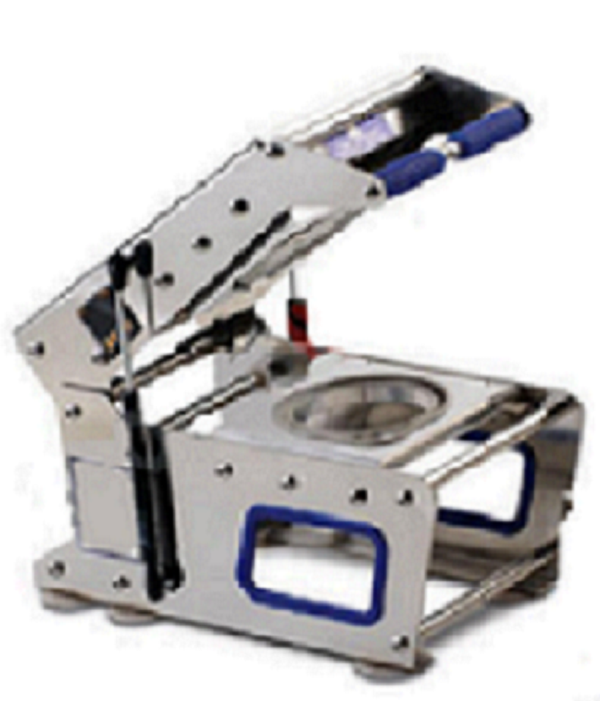

Double Glass & Cup Sealing Machine

Price 19000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 240 Volt (v)

Dimension (L*W*H) : 16 x 8 x 11 Inch (in)

Automation Grade : Manual

Weight : 14 Kilograms (kg)

Cup & Glass Sealing Machine

Price 16500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 240 Volt (v)

Dimension (L*W*H) : 16 x 8 x 11 Inch (in)

Automation Grade : Manual

Weight : 14 Kilograms (kg)

Manual Cup Sealing Machine

Price 16500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 300 Watt (w)

Dimension (L*W*H) : 16 x 8 x 11 Inch (in)

Automation Grade : Manual

Weight : 14 Kilograms (kg)

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry