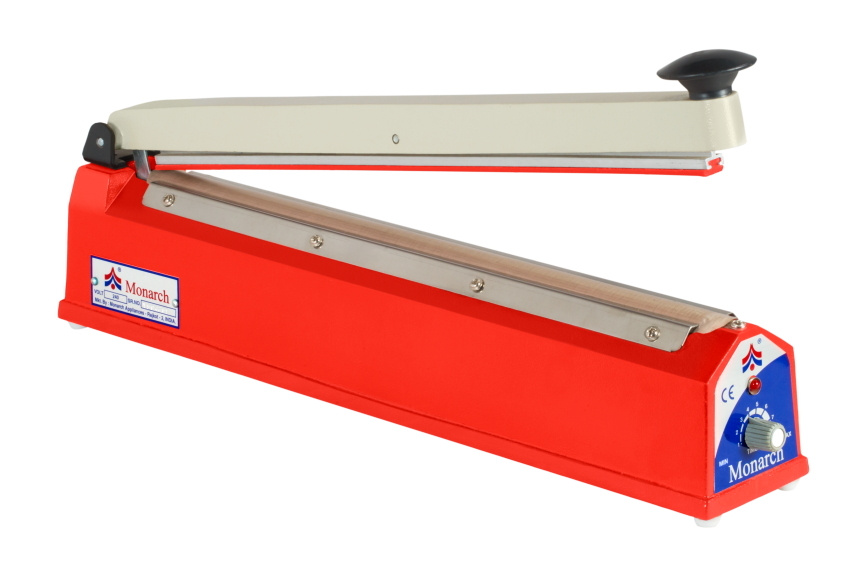

Continuous Band Sealing Machine

Price 33000.0 INR/ Piece

Continuous Band Sealing Machine Specification

- Dimension (L*W*H)

- 16*34*12 Inch (in)

- Power

- 220 Volt (v)

- Contact Load

- upto 8 kg

- Sealing Speed

- 0 TO 12 MTR / MIN

- Packaging Speed

- 10 Pieces/Minute

- Packaging Material

- BOPP, MULTI LAYER, LAMINATED, ALU.FOIL, LD, PP, HD, HM, POLYSTERPOLY

- Sealing Length

- 12 MM

- Condition

- New

- Type

- Manual

- Automation Grade

- Semi Automatic

- Voltage

- 220 Volt (v)

- Color

- Silver

- Weight

- 30 Kilograms (kg)

- Driven Type

- Hand Opereted

Continuous Band Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Continuous Band Sealing Machine

Horizontal ContinuousMachine:

A horizontal continuous sealer machine is designed for sealing flexiblepackaging materials such as bags or pouches in a horizontal orientation. Thistype of sealer is widely used for packaging a range of products including food,pharmaceuticals, and industrial goods. Horizontal sealers are ideal forhandling products that are packaged in a horizontal format, allowing forefficient and consistent sealing.

|

PRODUCT SPECIFICATION |

|

|

Product Name |

Continuous Bag Sealer - Horizontal (S.S. Body) |

|

Machine Weight |

30 kg |

|

Power Consumption |

600 Watt (220 Volt) |

|

Load Capacity |

upto 8 kg |

|

Sealing Width |

12 MM |

|

Machine Dimensions in Inch (L X W X H) |

16" x 34" x 12" |

Efficient Sealing Performance

Engineered to handle a wide range of packaging materials, this band sealing machine offers exceptional performance. It achieves a sealing speed of up to 12 meters per minute, allowing for continuous operation with minimal downtime. Its versatile capabilities make it ideal for small to medium-scale manufacturing and supply operations.

User-Friendly Manual Operation

The machine combines semi-automatic and manual functionality through a hand-operated design, making it simple for operators to manage. The integrated Human Machine Interface provides easy control and monitoring, ensuring smooth operation and quick adjustments according to packaging needs.

Durable Construction for Long-Term Reliability

Crafted from high-quality plastic, with a sturdy silver finish, the machine is built to withstand repetitive use in industrial environments. It offers a balance of lightweight portability and robust construction, supporting a workload of up to 24-30 kilograms and suitable for contact loads of up to 8 kilograms per session.

FAQs of Continuous Band Sealing Machine:

Q: How do you operate the Continuous Band Sealing Machine manually?

A: To operate the machine manually, place the filled packaging material between the sealing bands, adjust the Human Machine Interface controls for temperature and speed, and use the hand-operated lever to initiate the sealing process. The semi-automatic function ensures precise sealing with minimal effort.Q: What types of packaging materials can this sealing machine handle?

A: The machine supports various materials, including BOPP, multilayer, laminated films, aluminum foil, LD, PP, HD, HM, and polyesterpoly, making it suitable for diverse packaging applications across industries.Q: When is this machine ideal for use?

A: It is best suited for small to medium-scale manufacturing units or suppliers needing efficient, high-speed packaging. Businesses handling up to 15 kg/hr or packaging up to 10 pieces per minute will benefit from its capabilities.Q: Where can the Continuous Band Sealing Machine be installed?

A: Given its compact size and moderate weight (2430 kg), the machine can be installed on production floors, packaging workstations, or workshop environments in manufacturing plants. It requires access to a 220 Volt power source.Q: What is the process of sealing with this machine?

A: The sealing process involves loading the product into the packaging, positioning the bag under the band sealer, and engaging the manual drive. The machine applies a controlled temperature to seal lengths of up to 12 mm, with the entire process overseen through the control system.Q: What are the benefits of using this band sealing machine?

A: Benefits include faster packaging speed, compatibility with multiple packaging materials, consistent seal quality, reduced operational fatigue due to hand-operated design, and a reliable build that ensures long-term service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Bag Sealing Machine Category

Powder Packing Machine

Price 99000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 60 Kilograms (kg)

Automation Grade : Semi Automatic

Dimension (L*W*H) : 22 Inch (in)

Power : 220 Volt (v)

Tea Packing Machine

Price 52500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 40 Kilograms (kg)

Automation Grade : Semi Automatic

Dimension (L*W*H) : 21 X 41 X 36 Inch (in)

Power : 220 Volt (v)

Auto Parts Packing Machine

Price 27000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 24 Kilograms (kg)

Automation Grade : Semi Automatic

Dimension (L*W*H) : 16 x 34 x 12 Inch (in)

Power : 220 Volt (v)

Vertical Band Sealer

Price 31000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 32 Kilograms (kg)

Automation Grade : Semi Automatic

Dimension (L*W*H) : 17 X 34 X 31 Inch (in)

Power : 220 Volt (v)

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry