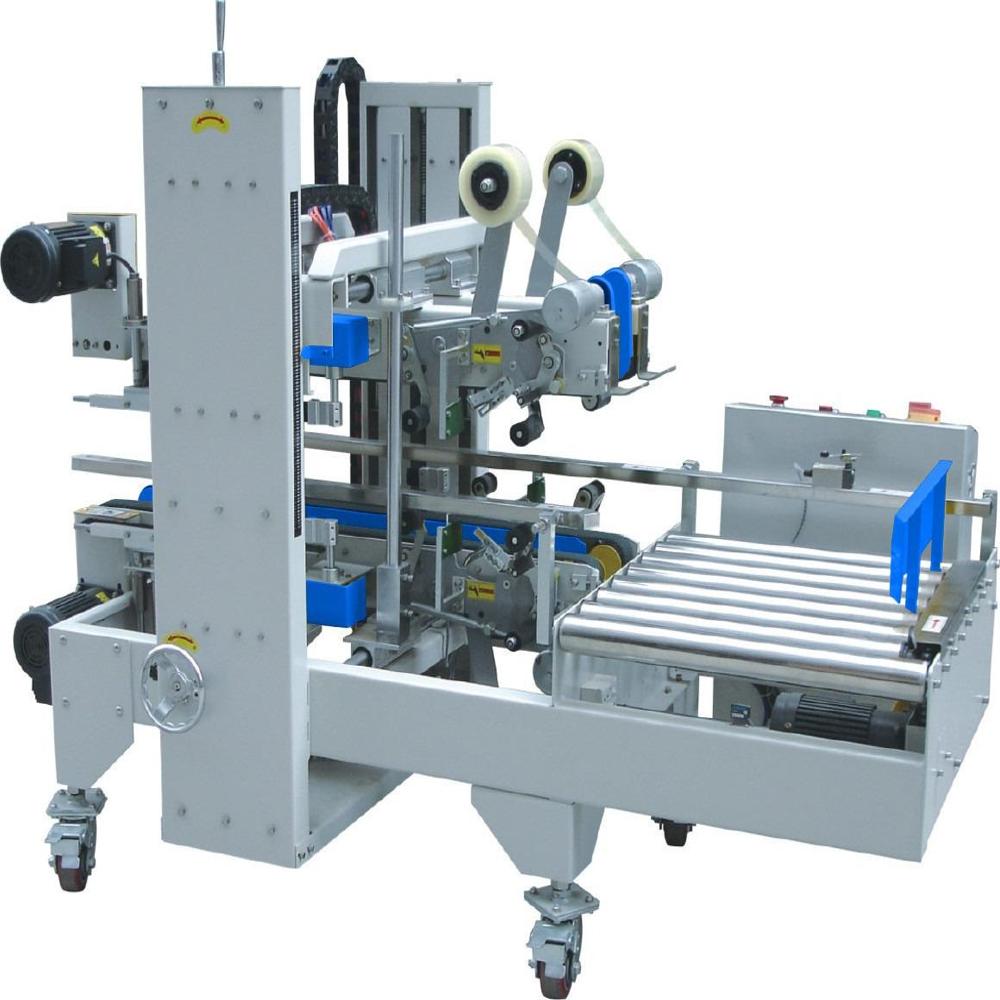

Corner Edge Sealing Machine

Price 800000.0 INR/ Piece

MOQ : 1 Piece

Corner Edge Sealing Machine Specification

- Power Supply

- 220/ 380V AC , 50/60Hz , 1/3 Phase

- Type

- Packaging Line

- Feature

- Heavy Duty Machine

- Capacity

- 18 Pcs/min

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Power

- 600 Watt (w)

- Voltage

- 220 Volt (v)

- Weight (kg)

- 550 Kilograms (kg)

- Dimension (L*W*H)

- Millimeter (mm)

- Color

- White

- Warranty

- 1 Year

Corner Edge Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 2 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Corner Edge Sealing Machine

The box sealing machine Semi automatic corner sealing machine is the box through the front section of the box sealing machine middle up and down, into the 90 degree corner machine, push the box plate into the corner sealing machine, seal the four corner, to achieve "H" type sealing. Sealing speed,sealing corner without folds, the carton upper and lower four corners at the same time automatically sealing smoothing.*Product Specification :

Tape Width -48mm to 72mm

Speed -18 CARTON/ MIN

Air Pressure -6kg / cm

Power Supply -220/ 380V AC , 50/60Hz , 1/3 Phase

Power Requirement -600 W

Machine Dimension -2000 X 1500 X 1500 mm

Efficient Semi-Automatic Edge Sealing

Combining power and precision, this Corner Edge Sealing Machine streamlines packaging lines with a semi-automatic design. The integration of a Human Machine Interface makes controls simple and responsive, reducing human error and ensuring consistency in every package, even under heavy-duty conditions.

User-Friendly Control System

Outfitted with an intuitive Human Machine Interface, operators can easily adjust settings for different carton sizes and sealing requirements. This results in reduced training times and increases operational efficiency across various packaging environments.

Built for Durability and Performance

Weighing 550 kg, this robust machine is engineered for longevity and uninterrupted performance. Its heavy-duty construction ensures that it can handle high-volume usage, providing reliable output for exporters, manufacturers, and suppliers alike.

FAQs of Corner Edge Sealing Machine:

Q: How does the Corner Edge Sealing Machine operate?

A: The machine uses a semi-automatic process where operators load cartons, and the system seals the corners using advanced mechanisms. The Human Machine Interface allows for easy adjustment and smooth operation.Q: What types of cartons or materials is this machine suitable for?

A: This sealing machine is ideal for standard cardboard cartons typically used in export and manufacturing packaging lines. Its designed for a variety of box sizes, ensuring strong and uniform seals at each corner edge.Q: When should regular maintenance be performed?

A: Its recommended to schedule routine maintenance checks every few months or after a significant number of cycles, especially under heavy usage, to ensure optimal performance and to prolong the machines life.Q: Where can the machine be installed within a packaging facility?

A: Thanks to its robust build and user-friendly interface, the machine can be seamlessly integrated into most modern packaging lines, ideally placed near carton assembly or other sealing equipment for a streamlined workflow.Q: What is the process for adjusting settings on the sealing machine?

A: Adjustments can be made through the Human Machine Interface, where operators can fine-tune parameters such as carton size or sealing pressure to match specific packaging requirements.Q: How does this machine benefit exporters and manufacturers?

A: By offering a rapid sealing capacity of 18 pieces per minute and consistent, reliable seals, the machine ensures that sensitive products are well protected during transit, reducing damage rates and supporting efficient shipping operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Tapping Machine Category

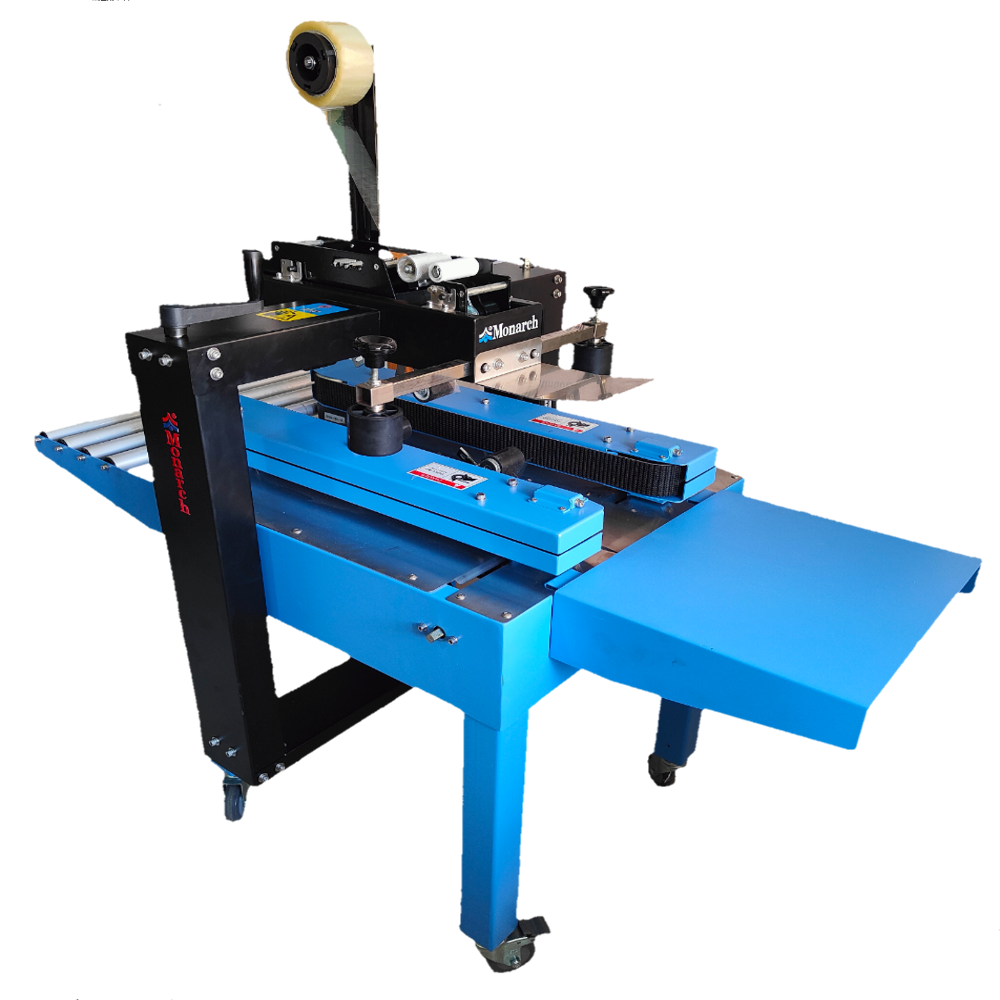

Case Sealer

Price 92000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 220 Volt (v)

Voltage : 220 Volt (v)

Warranty : 1 Year

Color : Blue

Carton Tapping Machine

Price 95000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 180 Watt (w)

Voltage : 220 Volt (v)

Warranty : 1 Year

Color : Blue

Auto Flap Closer Machine

Price 340000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 400 Watt (w)

Voltage : 220 Volt (v)

Warranty : 1 Year

Color : White

Carton Sealing Machine Side Belt Driven

Price 98000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 600 Watt (w)

Voltage : 440 Volt (v)

Warranty : 1 Year

Color : Silver

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry