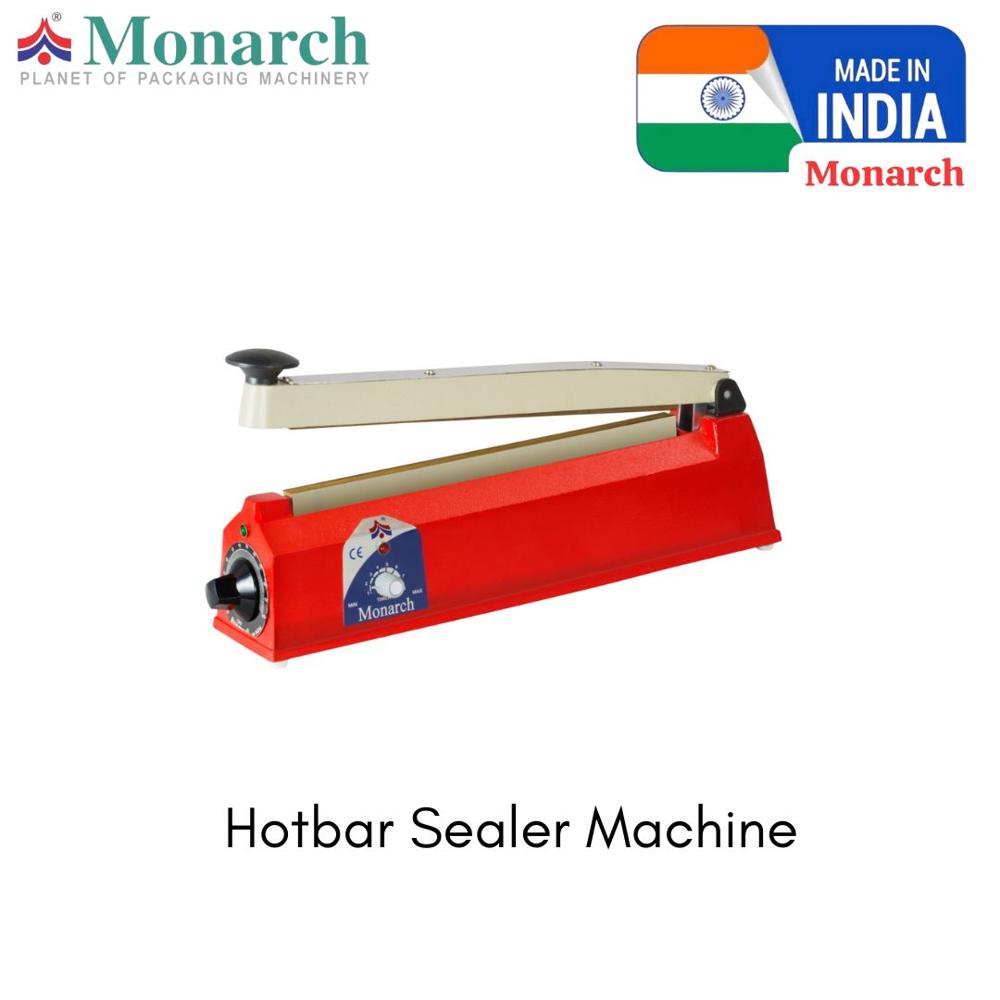

Hot Bar Sealing Machine

Price 4250.0 INR/ Piece

Hot Bar Sealing Machine Specification

- Sealing Length

- 12 mm

- Driven Type

- Hand Operated

- Condition

- New

- Seals Type

- Pouch seal

- Color

- Red

- Dimension (L*W*H)

- 450 X 95 X 210 Millimeter (mm)

- Packaging Speed

- 5 Bag Pieces/Minute

- Type

- Hand Sealer

- Filling Capacity

- 5 Pcs/min

- Packaging Material

- Plastic Bag

- Automation Grade

- Manual

- Contact Load

- upto 5kg

- Sealing Type

- Seal

- Voltage

- 240 Volt (v)

- Weight

- 5 Kilograms (kg)

- Sealing Speed

- 5 pics/min

- Power

- 240 Volt (v)

Hot Bar Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Hand Operated machine

- Main Export Market(s)

- Asia

- Main Domestic Market

- West India

- Certifications

- Certificates: CRISIL, ISO: 9001:2015

About Hot Bar Sealing Machine

Hand Sealer Machine:

A hand sealer machine is a manual device used to seal plastic bags,pouches, and other flexible packaging materials. It operates by applying heatto the edges of the packaging material, creating a secure, airtight seal. Handsealers are valued for their simplicity, portability, and effectiveness insmall to medium-scale packaging operations.

|

PRODUCT SPECIFICATION |

|

|

Product Name |

Hand Sealer - Hotbar |

|

Power Supply |

240 Volt AC |

|

Power Consumption |

700 Watt |

|

Sealing Length |

300 MM (12") |

|

Sealing Width |

12 MM |

|

Dimensions in MM (L X W X H) |

450 X 95 X 210 |

Efficient Manual Pouch Sealing

Experience fast and uniform sealing with this user-friendly hand sealer. Designed to process up to five bags per minute, the machine is suitable for packing plastic bags and pouches with maximum accuracy, ensuring strong and secure seals every time. Its compact dimensions enable convenient integration in limited workspace environments.

Durable Construction and Reliable Performance

Manufactured using quality plastic components, this sealing machine guarantees longevity and consistent results. Its manual operation provides straightforward control, reducing maintenance and downtime. The machines sturdy build supports up to 5 kg contact loads, making it a robust partner for regular sealing duties.

Ideal Choice for Small-Scale Packaging Needs

Whether you are an exporter, manufacturer, or supplier, this hand-sealing machine is tailored to meet moderate production demands. Its portability, low power consumption (240V), and practical sealing speed fit small operations, businesses, and workshops perfectly, optimizing packaging efficiency without the need for complex automation.

FAQs of Hot Bar Sealing Machine:

Q: How does the Hot Bar Sealing Machine operate for sealing pouches?

A: This machine uses a manually operated hand lever that applies heat through the hot bar to seal plastic bags or pouches. Simply place the edge of the pouch between the sealing bars and press the lever for a strong, reliable seal.Q: What is the recommended usage process for optimal sealing performance?

A: For best results, ensure the plastic pouch is properly aligned between the sealing bars. Close the hand-operated lever firmly, wait for a few seconds to allow the heat to seal the material, then release. The process can be repeated for up to five bags per minute.Q: When is it advantageous to use a manual sealing machine over automatic models?

A: Manual sealing machines are ideal for small-scale operations, limited budgets, or when packaging speed and volume are moderate. They offer precise control and require minimal training, making them beneficial for workshops and small businesses.Q: Where can the Hot Bar Sealing Machine be installed for packaging tasks?

A: Thanks to its compact design (450 x 95 x 210 mm), this machine fits easily on standard workbenches or tables in factories, packaging areas, small industrial units, and commercial outlets across India.Q: What type of packaging material works best with this sealer?

A: This machine is designed specifically for plastic bags and pouches. It ensures tight, leak-proof seals on various plastic materials used in packaging applications.Q: What benefit does the machines manual drive offer for users?

A: A manual drive provides greater control over the sealing process and is easy to operate and maintain. It eliminates the complexity of computerized systems, making it reliable and straightforward for daily use.Q: How is warranty support managed for the Hot Bar Sealing Machine?

A: The manufacturer offers a 6-month warranty on this sealing machine, ensuring prompt assistance for any defects or issues within the warranty period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Sealing Machine Category

Hand Sealer Machine

Price 1840.0 INR / Piece

Minimum Order Quantity : 1 Piece

Sealing Length : 1.6 mm

Driven Type : Hand Operated

Dimension (L*W*H) : 420 x 85 x 250 Millimeter (mm)

Condition : New

Liquid Sealer Machine

Price 2800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Sealing Length : 8 INCH

Driven Type : Hand Operated

Dimension (L*W*H) : 470 x 190 x 270 Millimeter (mm)

Condition : New

Impulse Sealer

Price 1800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Sealing Length : 10 INCH

Driven Type : Hand Operated

Dimension (L*W*H) : 350 x 85 x 240 mm Millimeter (mm)

Condition : New

Hand Sealing Machine

Price 1160.0 INR / Piece

Minimum Order Quantity : 1 Piece

Sealing Length : 1.6 MM

Driven Type : Hand Operated

Dimension (L*W*H) : 320 x 85 x 250 Millimeter (mm)

Condition : New

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry