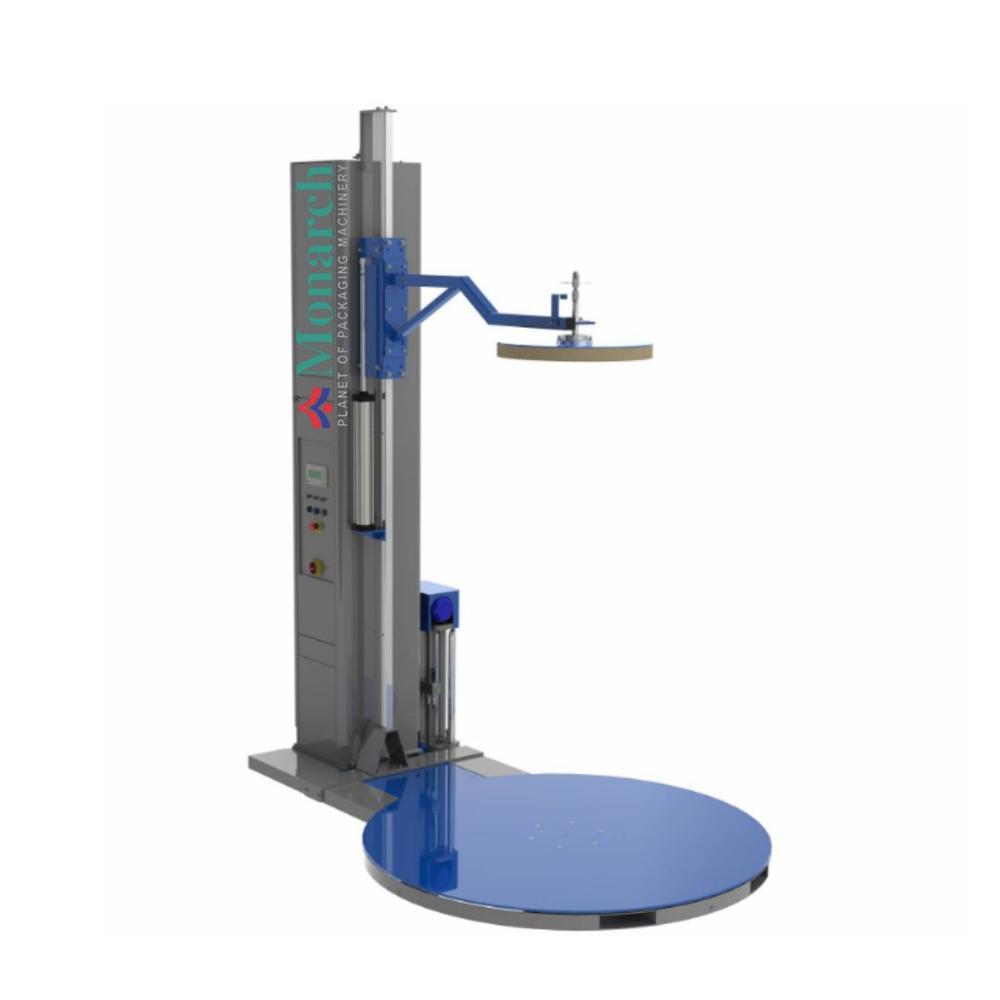

Pallet Stretch Wrapper

Price 338000.0 INR/ Piece

Pallet Stretch Wrapper Specification

- Material

- Shrink film

- Capacity

- 1 Pcs/min

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220 Volt (v)

- Power

- 220 Volt (v)

- Weight (kg)

- 600 Kilograms (kg)

- Color

- white & blue

- Warranty

- 6 MONTH

Pallet Stretch Wrapper Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Rajkot

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 3 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Carton Packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- CE, CRISIL, ISO:9001:2015

About Pallet Stretch Wrapper

Since inception, we are looked up as notable manufacturer and supplier of an utmost assortment of pallet stretch wrapping machine. Our machine is used for pallet wrapping of electric parts, metal pails, roll paper, household goods, electronic components and cosmetics. This pallet stretch wrapping machine is made from the best quality materials at our state of the art machining facility, in-sync with globally laid quality standards. We are capable of customizing these machines as per the requirement of the clients.

It has heavy duty turn table to maintain all industrial applications

- Provides moisture-proof wrapping of pallets

- Modular construction, user friendly design and durable service are some of its salient features

-

Pallet stretch wrapping machine Key Features:

- No technical Skill Required for but high knowledgeable person required for that cycle of operation is completely automated.

- Its Fully automatic machine and Low man resource power

- Its has Heavy duty turn table to Maintain all industrial applications.

- Having Modular in construction and Sturdy mast machined guide ways for guiding the stretch unit.

- Wide range of stretch film material having Compact stretch unit

- They Provide moisture-proof wrapping of pallets at Reasonable Price

Technical Specification

Type of Machine

Pallet stretch wrapping machine

Wrapping Range

L min. * W min.- 500 mm * 500 mm

L max. * W max

L max. * W max -1300 mm *1300mm

Turntable diameter

1650 mm

Turntable Height

85 mm

Turntable weight capacity

2000 kg

Wrapping weight

1800 mm

Machine weight

600 kg

Power Supply

220 V 50/ 60 Hz 1 Phase (Standard )

Packing efficiency

20-40 loads/ hour

Film thickness

17-35 mm

Film Depth

500 mm

Core Diameter

76.2 mm

Maximum Film. Diameter

260 mm

Max . weight of film roll

5 kg

We commenced the business operation in the year 2004 asa leading manufacturer and exporter of Portable Conveyors. These conveyors are designed and manufactured by our professionals as per the set industry norms using supreme grade materials. We offer these machines to clients at reasonable prices.

We have carved a niche for ourselves in the market under the able guidance of our director,Mr.Bhavesh Mehta. His immense domain knowledge and acute business skills have helped us grow by leaps and bounds. His untiring zeal and passion for success motivate other team members to work hard and move forward. We would like to introduce ourselves as pioneer manufacturers of packaging machinery based at Rajkot (India) under the well-known brand name poly seal. We manufacture sealing machine, filling

Advanced PLC Control for Streamlined Operation

This pallet stretch wrapper utilizes a PLC (Programmable Logic Controller) system to enhance operational precision and reliability. The intuitive controls facilitate both automatic and semi-automatic modes, allowing flexibility in wrapping diverse load sizes. With high capacity and easy-to-use features, it streamlines packaging lines in warehouses and manufacturing units.

Flexible Usage for Varied Pallet Dimensions

Catering to pallet sizes from 500 mm x 500 mm up to 1,050 mm x 1,200 mm, the machine adapts to a wide range of packaging requirements. It can wrap up to 1,500 kg of load per cycle, making it ideal for industries with different shipment sizes. The robust construction ensures dependable performance even with heavy loads.

Reliable Performance with Energy Efficiency

Operating on 220V single-phase power at 50/60Hz, the stretch wrapper is engineered for efficiency and ease. Its shrink film wrapping process not only secures goods efficiently but also minimizes material waste. The machine is designed for longevity and backed by a 6-month warranty, ensuring consistent operation and peace of mind.

FAQs of Pallet Stretch Wrapper:

Q: How does the PLC control system improve the pallet wrapping process?

A: The PLC control system enhances the machines precision and reliability by automating key operations. This allows users to set and monitor parameters easily, ensuring consistent film application and secure packaging for pallets of various sizes.Q: What types of pallets can be wrapped with this machine?

A: This stretch wrapper is suitable for pallets with dimensions ranging from 500 mm x 500 mm to 1,050 mm x 1,200 mm. It accommodates a wide variety of load sizes, making it adaptable for many industries.Q: When is it best to use the automatic or semi-automatic mode?

A: Automatic mode is recommended for high-throughput packaging lines where efficiency and speed are crucial. Semi-automatic mode can be preferred for smaller batches or when special handling is required, offering more manual control.Q: What are the main benefits of using a pallet stretch wrapper with a PLC control system?

A: Key benefits include improved packaging consistency, reduced labor, enhanced load security, and minimized film waste. The PLC system also enables quick adjustments for different production needs, boosting overall productivity.Q: Where can this pallet stretch wrapper be installed?

A: This machine is well-suited for warehouses, distribution centers, and manufacturing facilities. Its durable design and moderate power requirements ease installation in standard industrial settings.Q: What is the process for using the machine?

A: Operators place the loaded pallet on the turntable, select settings via the PLC panel, and start the machine. The wrapper then automatically applies shrink film around the load, securing it for storage or transport.Q: What warranty and after-sales support are provided?

A: The stretch wrapper comes with a 6-month warranty against manufacturing defects. Manufacturers and suppliers offer dedicated after-sales support, including assistance with installation, operation, and troubleshooting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pallet Stretch Wrapping Machine Category

Pallet Wrapping Machine with Pressing System

Price 508000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue

Material : Other

Weight (kg) : 650 Kilograms (kg)

Warranty : 6 month

Pallet Stretch Wrapping Machine

Price 364000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Material : CARTON PACKING

Weight (kg) : 600 Kilograms (kg)

Warranty : 6 Month

Robot Stretch Wrapper

Price 700000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue

Material : Steel

Weight (kg) : 430 Kilograms (kg)

Warranty : 1 Year

|

MONARCH APPLIANCES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry